Summary

Of all the faults that Virtjoule can detect, refrigerant leaks generally give the most warning. In most cases there is plenty of time to fix the problem before it becomes critical and before you have to spend money on expensive overtime or disrupt your business.

That being said, this article has a unique perspective in that it covers a refrigerant leak that progressed from normal to total failure before being addressed.

Key Concepts

- Refrigerant leaks cause very common behavior changes in a condenser or package unit that can be detected by Virtjoule

- Most refrigerant leaks occur slowly enough that they don’t have to turn into crises

- It’s simple to measure and show that a fix has worked

- Temperature is a lagging indicator of a problem. By the time temperature control is lost, the failure has already occurred. Runtime and cycle monitoring can give warnings of impending failure days in advance.

The Setup

I will run through a set of six charts, one per day, that illustrate various phases of runtime behavior that we saw when a walk-in split system was on its way to total failure.

Not surprisingly, refrigerant leaks can occur at various rates. Some occur over months while others, once developed, can progress over the course of a few days. We have the luxury of monitoring a unit whose leak progressed at a very specific rate, day by day, over the course of six days, each day exhibiting a new and interesting behavior.

From experience, we see split systems are much more prone to leaks. This is primarily because there is more custom-installed refrigerant line and longer runs with more field soldered joints. These installations often have to work around difficult building designs, turning several corners along the way. In many cases a split system may be installed well after the building was built. Computer room air conditioners (CRAC units) are one example. Another is restaurants where a new walk-in refrigerator is added to a space that lacked one before.

Package units can also develop refrigerant leaks, but our experience shows us this scenario is rarer. Because refrigeration circuits are built at the factory, they can be subjected to higher quality standards. Because the compressors, condenser, and evaporator are all in the same unit, there are fewer things to go wrong and fewer people coming together to make the thing work. It can more easily be pressure tested before being shipped.

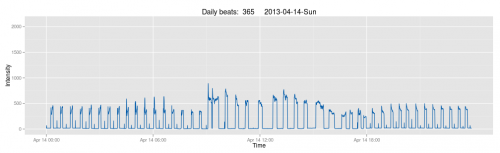

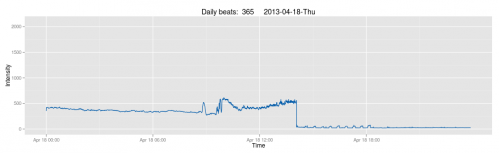

Phase I – Normal Operation

One of the nice things about 24/7 monitoring is that you can easily determine what is normal. This is a normal looking cycling pattern for a walk-in condenser unit. Very regular cycles in lower load times of the day. Cycle times stretch out a little and intensity increases when the unit is under the most load: from opening at around 9 am through to about 6 pm.

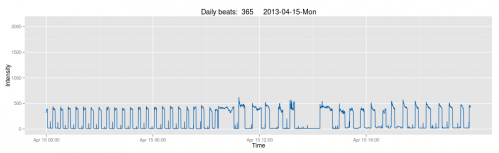

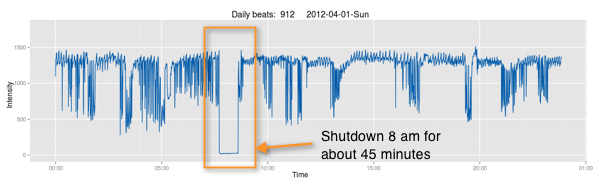

Phase II – Unexplained shutdown for 1.5 hrs

On Day 2, we called a fault at around 2 pm because there was a non-operation alert indicating that the unit had not come on for about an hour and a half, something that was very unusual for this machine. You can also see that cycle times before the shutdown were much longer than the day before.

The unit started up again on its own. The next cycle was understandably longer as the unit worked to catch up with the demand caused by no runtime for 1.5 hrs. Notice that all of the cycles after that were longer than the day before, even when the unit didn’t have as much load.

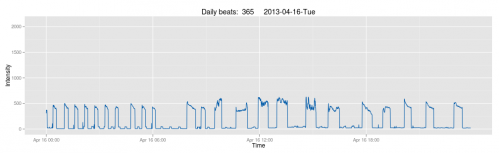

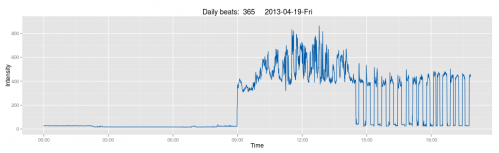

Phase III – Erratic cycling

The slightly elongated cycles continued throughout the next morning. At 6 am there was another unexplained shutdown which triggered a non-operation alert. From then on, cycles became much longer with longer shutdowns than normal in between.

By now, even an untrained observer of these graphs could tell you that Day 3 of runtime looks a lot different than Day 1.

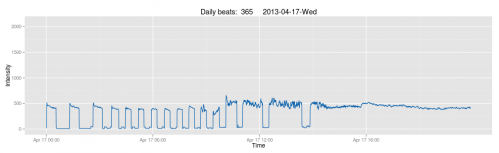

Phase IV – Failure begins

Notice that the morning cycles continued at much longer intervals indicating that the unit is still working hard to keep up. Around 10:30 am, both the intensity jumped as well as the cycle times started to lengthen each and every cycle. By the middle of the afternoon the unit was running non-stop.

Once a unit is running in a non-stop state like this, the only thing we can tell the customer is that the unit is almost certainly not meeting the cooling demand required. How long it will be from here before there is a noticeable temperature rise in the cooler depends on a lot of things: what time of day constant runtime began, how often the walk-in is accessed thereby placing more load on the cooler, whether the walk-in is a freezer or refrigerator, how much product is in the cooler, how big the cooler is, and what the air temperature is outside the cooler.

We get very nervous on behalf of the customer at this point. The clock is ticking and something should be done — soon.

Phase V – Total Failure

We confirmed for the client the next morning that the unit ran non-stop all night. We had no reason to believe the situation was going to get better as we’ve seen this degradation pattern a number of times before. The client confirmed that temperature was rising in the cooler. They had to crowd all of the product into another unit until the leak could be found and fixed.

The HVAC technician worked on it that afternoon, but had not confirmed the leak yet. The unit was not restarted.

Phase VI – The Fix

By the next day, the leak was located and fixed. The unit was restarted. A condenser unit will always run a long time until the cooler reaches the right cold temperature. This is normal. By about 6 pm the unit fell back into its normal cycle rhythm and has been running this healthy pattern ever since.

Conclusion

Because normal cycling behavior was well established for this unit, abnormal cycling behavior was very apparent, both to the eye and to our fault detection algorithms.

Unless a refrigerant line is physically damaged, most refrigerant leaks occur over much longer periods of time. The rate of the refrigerant leak will determine how long the customer has between fixes, if the leak is not found.

Condenser units often have plenty of capacity which is part of why they cycle as much as they do. A refrigerant leak can go for a quite a while until the condenser unit runs out of capacity to meet heat rejection demand. The pre-failure phases mentioned above can often be seen over the course of a few days or even a few weeks, giving the client ample time to address the problem before it turns into a crisis.

Temperature monitoring is a lagging indicator of a failure. By the time temperature control is lost, the failure is already mature and you’ve lost valuable time to get it repaired. Runtime and cycle monitoring the condenser unit can detect system wide degradation and failure sometimes giving days of warning. In this case there were indications of a major problem three days before the failure.

[Randy Cox - CEO and co-founder of Virtjoule - He is the software designer and analytics engineering for Virtjoule Sense sensors. He studied Chemical Engineering and Petroleum Refining at the Colorado School of Mines. You may contact Randy at: randy at virtjoule dot com]