Summary

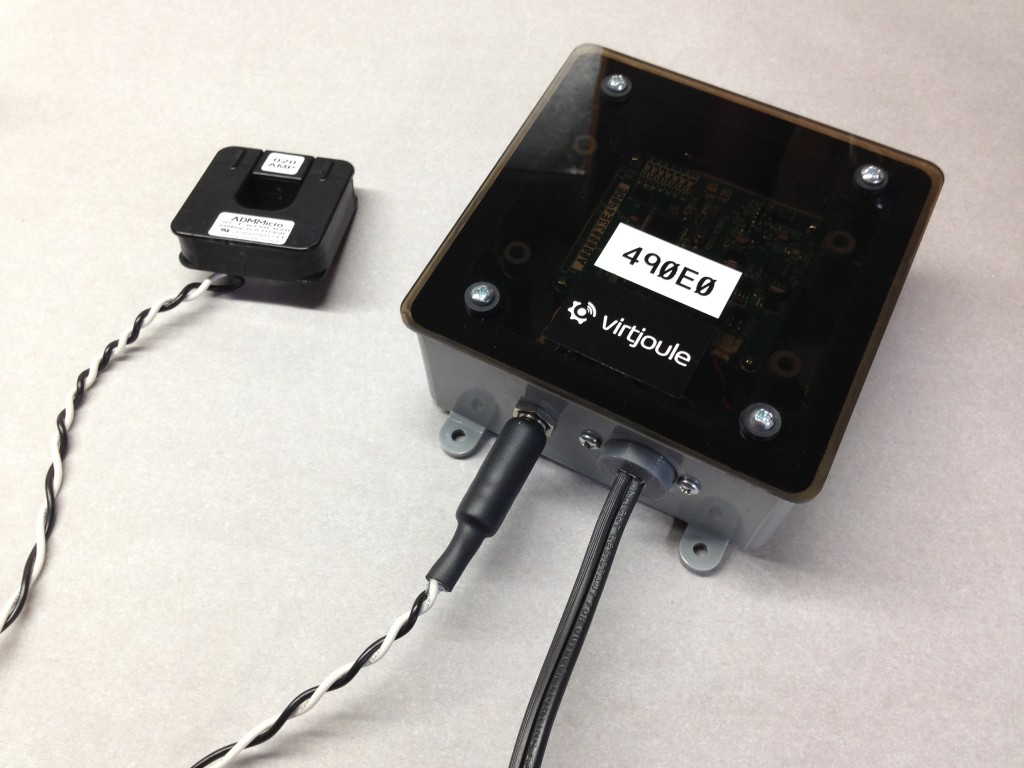

Virtjoule has been in production and in the field with a new Cellular CT device called Virtjoule Juice. It’s a new continuous monitoring system for amperage readings used on any type of equipment electric motors or other types alternating current draw.

The new Virtjoule Cellular CT has been calibrated with the Magnelab SCT-0750 line of industrial current transducers (CT) making it both accurate and flexible for reading amperages from 0 to 3,000 amps.

With the Virtjoule Cellular CT sensor and monitoring service, you can find problems such as short or long cycles, over or under amperage conditions, and after hours operations, all of which may indicate operational problems which should be corrected before becoming expensive repairs, large utility bills, or interrupting critical business processes.

Monitor Amperage and Power

Current transducers are a special type of sensor that can not only tell if current is flowing through an alternating current wire, it can also tell you how much amperage is flowing through the wire which is useful for both fault detection and energy studies.

First dedicated cellular CT on the market

This is the first low-cost dedicated cellular CT available on the market. Other CT products are available on the market, but they are either unconnected loggers that have to be retrieved and uploaded or are connected to gateway devices that cost well over $1,000 and don’t stand alone.

CT’s are sized and based on the electrical current used on one leg of an alternating current wire. Sizes can go from 5 to 200 amps in the SCT-0750 line and up to 3,000 amps on other parts of the Magnelab CT lineup.

A Must-Have Tool for Energy Auditors, Retro-Commissioning, and Service Providers

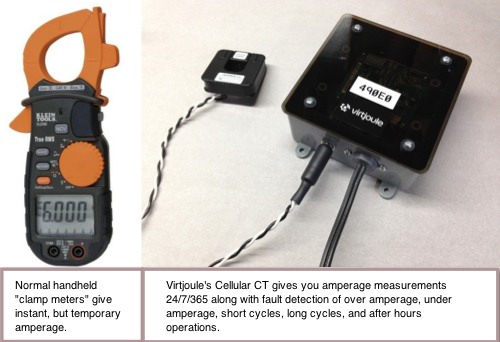

A cellular CT will become a must-have tool. Energy auditors, retro-commissioning specialists, and service providers are all aware of the basic usefulness of a regular handheld CT. 24/7/365 monitoring via CT gives you the ability to isolate a single component of a machine or the flexibility to find the variable energy use of an entire machine.

Virtjoule has been known for excellent fault detection capabilities and using a CT is now one more way to tap into fault detection capability in addition to understanding the energy usage of a machine.

True RMS

The Virtjoule Juice Cellular CT is a True RMS sensor. In addition to normal sinusoidal power feeds, it can be used to accurately measure amperage on variable speed devices and other pulse width modulated machines where computing the True RMS is key to knowing the correct amperage. Knowing correct amperage is critical to knowing how much power a machine is using and, for that matter, what parts of the machine are running.

How can you use a Cellular CT?

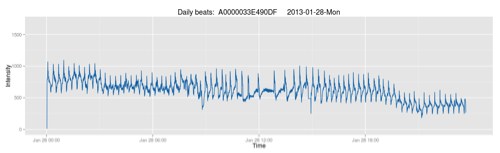

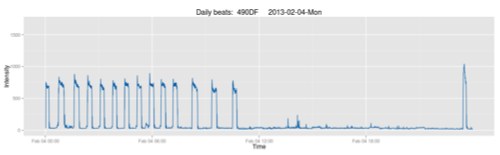

Cycling and hours of operation

Use the Cellular CT to pick up runtime information which includes amperage levels, cycling behavior, and hours of operation.

Failing compressors

It’s a well known fact that most aging compressors will begin to draw more amps, not only on startup, but at runtime as well. We have seen a recent example where amperage monitoring showed that a compressor was at the end of its life and we caught the actual failure when it happened. Monitoring amperage can give you insight into machine life expectancy issues.

Locating energy wasters

Use the Cellular CT to do sub-metering on selected units. With power output estimates from known amperage, it’s now possible to find those energy hogging machines.

Use the Cellular CT to demonstrate how much after hours operations cost. By monitoring the machine 24/7, you know when it is running after hours. Because you now have amp information, along with voltage and power factor it’s now possible to closely estimate how much after hours operations are costing. Virtjoule can help you do that.

Monitor complex behavior of individual components

Cellular CTs can be used to monitor specific electrical components of a much more complex machine. For instance, you can know conclusively at any time how many stages of compressors are being used in a large package unit. Also, estimating energy usage on larger and more complex machines can be very inexact because you can only estimate just exactly how the machine is used. Rules-of-thumb break down, particularly on larger machines. Now you can find out exactly how the machine is being used and how it’s performing.

Because amperage can be turned into power information and because we’re taking 10 second averages of amperage, you can get very accurate estimates of power usage on any electrical machine, motor, or other electrical component of a machine.

Multi-tenant situation, expense sharing

Do you have a multi-tenant situation, but sub-metering is not possible? Use Cellular CTs to understand power use across shared machines or electrical input and allocate costs appropriately and fairly.

Comparing a standard “clamp meter” with Virtjoule Juice Cellular CT

Available now

Virtjoule Juice Cellular CT is available now. Call us today to discuss how Virtjoule Juice Cellular CT can help you or your clients and get your order in for this first of a kind monitoring device.

[Randy Cox - CEO and co-founder of Virtjoule - He is the software designer and analytics engineer for Virtjoule Sense sensors. He studied Chemical Engineering and Petroleum Refining at the Colorado School of Mines. You may contact Randy at: randy at virtjoule dot com] – See more at: http://blog.virtjoule.com/