Summary

Virtjoule is proud to announce the availability of cellular HVAC and refrigeration monitors! With nearly a year of experience in the field with the cellular version of our monitors, all of our current customers have been converted from the short range radio based monitors. No longer will you need a netbook computer somewhere within radio range. No longer will you be at the mercy of the Internet connection at remote locations.

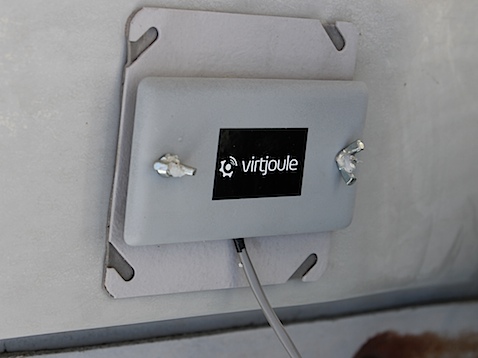

The vision we had when we started the company over three years ago is now finally a reality. That is, “parachute” onto a building, stick on and power up a sensor and begin collecting machine runtime data immediately and remotely without expensive installations, capital expense, or expensive integration projects with building automation systems.

Key Points

- Sensor comes already activated on one of the nation’s leading cellular providers: Click here

- All sensors are independent of each other. No more mesh network and the possibility of one weak link bringing down the whole sensor network.

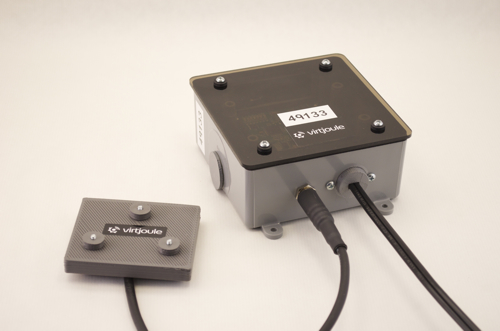

- Even easier install. New sensor is polarity independent, running on any power source from 12 VDC to 24 VAC. A standard RTU can be installed in less than 10 minutes.

- New web application features including automated short cycle fault detection.

- Built-in internal cellular antenna. External magnetic mount and direction antenna options are available for those really difficult locations.

- New, smaller, and lighter weight vibration microphone. Tape and screw mount options available.

The back story

When the first versions of Virtjoule HVAC monitors were developed over three years ago, they communicated over a low power and short distance radio network. This was the only way to create an economical sensor that could be applied to such a wide range of equipment, everything from large 125 hp pumps and fans on huge cooling towers to small beverage coolers.

Since that time a quiet revolution was taking place in what is now called “Machine to Machine” (M2M) applications. Cellular carriers like Verizon, AT&T, and many others were aggressively developing their growth plans and decided that much of their strategy would depend not on selling more handset devices, but selling more lines for sensors, tablets, and all sorts of devices that needed internet connectivity. Suddenly the price to acquire a cellular internet connection for a single device became an order of magnitude lower.

Virtjoule always knew that the mesh network radio based approach was an initial architecture. We didn’t know how or when we would be able to transition that architecture to fulfill our original vision.

Certified cellular device

One year ago, Virtjoule became a certified device for one of the nation’s leading cellular providers. We were approached by our business account representatives and the M2M specialists and we discussed moving Virtjoule to cellular. This was a process that took months of development, negotiations, learning, and investment. Since that certification, we have rolled out this new cellular sensor to all of our customers.

Say “No!” to obsolescence

A huge benefit to the Virtjoule way of monitoring is that no one actually buys the sensor. It is included in the monthly service cost. No Virtjoule customer was left holding an obsolete piece of equipment. We simply replaced everything in the field with our newest model and we all moved forward together.

If you’re ready for the advantages of true 24/7/365 HVAC and refrigeration monitoring that is independent of the local tenant or building internet connections, then get in touch with us so we can tell you how you can start today! Call 1-800-658-1864 or click on the contact link to tell us about yourself.

[Randy Cox - CEO and co-founder of Virtjoule - He is the software designer and analytics engineer for Virtjoule Sense sensors. He studied Chemical Engineering and Petroleum Refining at the Colorado School of Mines. You may contact Randy at: randy at virtjoule dot com]