Summary:

Is your package unit or split system cycling too much? How do you know? The correct answer is that it depends on the unit and the manufacturer. However, common sense can play a huge role in figuring out if your machines are excessively cycling. Finding out how often your machine is cycling and how long the cycle times are can tell you a lot about how healthy your machine is or whether you need to change your control regime.

In this article we’ll look at a case study of a 90 ton chiller from Carrier and how we helped a customer cut over 14,000 cycles per year in normal operation even when the chiller was operated on a building automation system (BAS) with a dedicated maintenance staff.

Key concepts: Excessive cycling and compressor short cycling can be controlled. Avoid excessive wear and tear on HVAC equipment. Stop excessive HVAC energy consumption and expense.

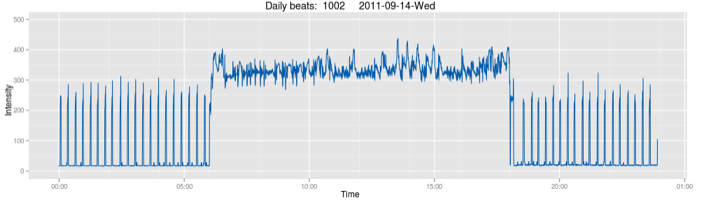

Let’s set the scene. This 90 ton Carrier chiller has normal operating hours of 6 am to 6 pm. We could tell that its start up and shut down times were programmed correctly because it’s obvious from the Virtjoule beat chart below that the unit is running all the time between those hours. The building was not occupied outside of 6 am to 6 pm and the owners of the building did not expect to see any unit operations in the off hours. However, you can see from the graph below that even though there was a noticeable shutdown, the unit continued to cycle on and off throughout the night and early morning hours.

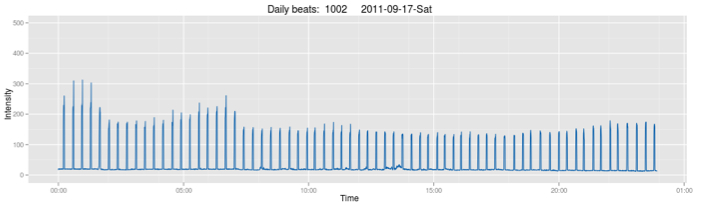

The extra cycles were typically 3-4 minutes in duration and numbered 40 or more per day and many more than that on weekends adding up to over 14,000 cycles per year of extraneous cycling and run time. That’s 14,000+ cycles and over 700 hours of extra run time not to mention that electric motors can take up to three times the amount of electricity to start them than it takes to run them. At common electricity rates all of this could add up to around $5,000 per year not to mention the wear and tear on a very expensive asset.

Here’s a snapshot of the run time graph for a typical day with out-of-hours cycling. You can see out-of-hours cycling through the early morning hours up to 6:00 am and then solid operation between the hours of 6 am and 6 pm. Out-of-hours cycling begins again at 6 pm and continues through midnight on this chart. The excessive cycling continues until 6 am the following day.

The following graph is how the machine operated on Saturdays and Sundays. Two out of the seven days of the week had close to 90 extraneous short cycles.

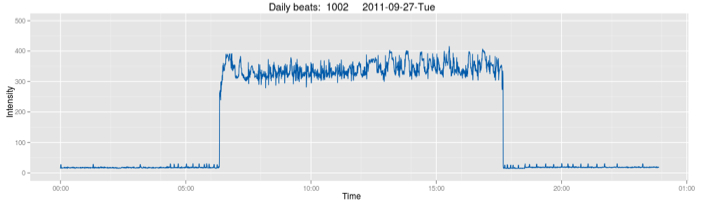

Keep in mind that this was the main cooling unit and was operated on a building automation system. Soon after this run time behavior was noted the building engineers were able to make control adjustments that completely eliminated the extra cycles. Now you can see a very clean start up and shutdown of this chiller each day. No extra cycles. No wasted energy. No unnecessary wear and tear.

If you’ve operated BAS before you are probably aware of how much work it can be to extract and analyze the data points that are available. We often hear that the BAS should catch these kinds of problems, but case after case has shown us that it isn’t happening. BAS has proven many times that it’s better at control than monitoring. Even when it’s used for monitoring it can cost hundreds of dollars per data point to extract and then someone has to interpret and monitor the results regularly. Maintenance organizations often have more urgent needs to attend to in their building and this sort of problem doesn’t usually cause immediate comfort problems in the building.

The steady burning of electricity and asset wear should make for a foul smell of burning money to someone in the building and so this should be a comfort problem under someone’s seat eventually. The top maintenance organizations that we see deal with the issues of comfort, maintenance, energy conservation, and cost every day in their operations. They like things to run well and to cost the least amount possible. Fortunately those things usually go hand in hand. With Virtjoule, after a 1 hr installation and setup, a few days later we had enough information to show that a change was needed. The owners of the building were able to get their maintenance organization to make the changes and make an immediate difference on the healthy operation of this unit.

[Randy Cox - CTO and VP of Software Engineering, Virtjoule - is the software designer and analytics engineering for Virtjoule Sense sensors. You may contact Randy at: randy at virtjoule dot com]

|