Summary: High head pressure faults can occur on air conditioners for a number of reasons. This article will discuss two scenarios where high head pressure faults occurred because of two distinct and common problems.

The first problem occurred when Liebert computer room air conditioner condenser fins were blocked by cottonwood seeds. The second example was caused by a faulty condenser fan that would not turn on.

You will see that both instances left distinctive signatures or patterns that Virtjoule’s beat charts were able to show. I will review the basics of the refrigeration cycle which can help you understand why these two problems caused a high head pressure fault.

Key concepts:

- High head pressure faults leave distinctive signatures.

- Short cycling can be an indicator of a high head pressure fault.

- The refrigeration cycle can help you understand the probable causes.

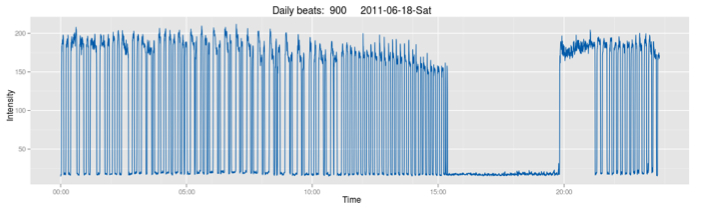

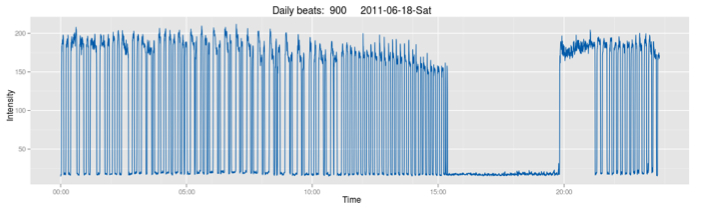

Even though HVAC units often live on top of roofs, it doesn’t mean they are immune to the environment around them. The first example of a high head pressure fault occurred at a customer’s data center and office building in Fort Worth, Texas. It was the middle of June and spring was winding down and one of the hottest summers on record in Texas was beginning to bear down on the state. Below you can see the temperature graph for that day which topped out at 105 degrees just after 4 pm.

Temperature graph for Fort Worth on June 18, 2011

These Liebert units can show short cycling where they will turn on for just minutes and then off again for minutes. According to sources we’ve talked to they are designed to handle this because many customers of computer room air conditioners want to have fairly constant temperatures.

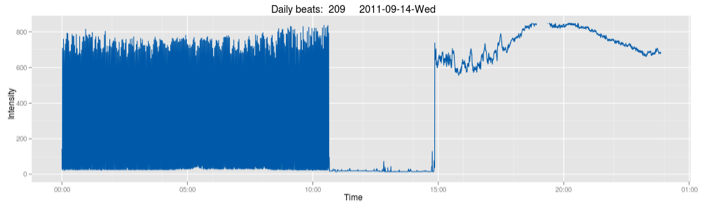

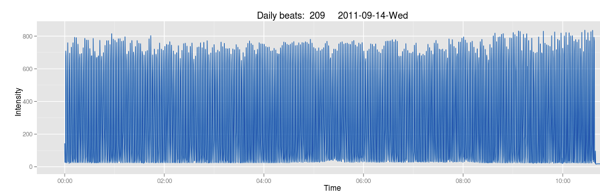

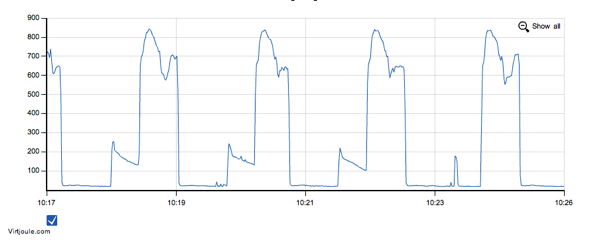

You can see from the graph below that just after 11:00 am the lines get even closer together and denser indicating that the unit is cycling on and off even more frequently. This was not normal behavior and was the first indication that there was a problem developing.

At 3:21 pm the unit shut down completely. There were two Liebert units providing cool air to a data center room housing about $1.5 million in equipment. On warm days, both units are required to cool the load generated there. A Virtjoule alert was sent to the customer who was able to get the unit back up and running before they had to take any drastic measures to reduce the load in the center by turning off machines. This also averted the associated lack of service to their customers not to mention all the extra time it takes their IT staff to shutdown and restart a large server system.

High head pressure fault on computer room air conditioner

What happened to cause this problem? The Liebert control panel in the data center indicated a high head pressure fault had occurred, but no alert from that system was sent. After our alert to the customer, their authorized Liebert representative was called out and determined that the condenser coils had been blocked by cottonwood seeds in the air getting trapped in the fins by the draft going through the condenser. The unit was cleaned and restarted even though the unit had recently been cleaned.

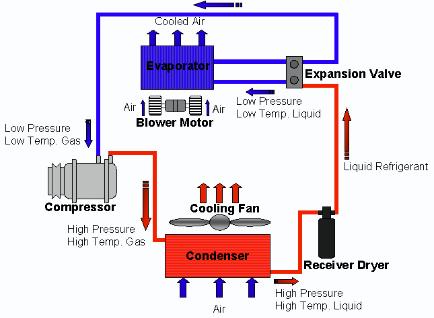

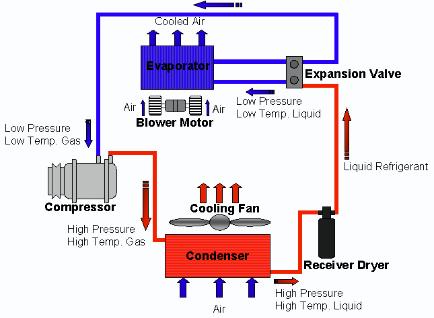

The refrigeration cycle

If you had a situation that said “High head pressure fault” do you know what was really happening in the machine and what might cause it? Let’s review the refrigeration cycle where it will be easier to understand the sources of a high head pressure fault.

Refrigeration cycle illustration

The refrigeration cycle depends on the laws of physics for refrigerants going through a phase change from high pressure liquid to low pressure gas and back to a high pressure liquid. So how does this high pressure liquid actually cool itself? The answer lies in the thermal expansion valve (TX, TXV, TEV). It controls the pressure drop from the high to the low pressure side of the refrigerant cycle. The expansion valve is basically a constriction of the refrigerant line that accomplishes a pressure drop across the valve. By definition if you have pressure on one side of a valve and the valve is letting fluid move, then the fluid on the other side of the valve will be at a lower pressure.

Expansion (drop in pressure) of the high pressure liquid refrigerant will flash evaporate roughly half of the refrigerant prior to it being introduced to the evaporator. Think about water that boils more quickly when you’re at altitude (lower atmospheric pressure). It’s pressure that is holding the refrigerant in a liquid form and when that pressure is released that mixture wants to boil.

Because this mixture is not having heat added or removed at this time, the phase change from liquid to saturated liquid/gas will cause the mixture to radically drop in temperature. This is because energy in the form of heat is being converted to a new form or energy to support part of the refrigerant in gaseous form.

Heat is lost to the formation of the gaseous form of the refrigerant. This heat loss is called the heat of evaporation. It’s the amount of heat needed to change a liquid to a gas. You can add heat to the system to create the heat of evaporation (the burner adding heat to boil water on a stove) or the heat energy required can be pulled from the original mixture or its surroundings if the pressure is low enough and there is no other source. Since the pressure is reduced the refrigerant is going to be forced into a phase change and it will literally suck heat out of the mixture to do it causing a large drop in temperature.

Refrigerants are simply special compounds or mixtures that exhibit very specific phase changes at convenient temperatures and pressures. Many liquids could be used as a refrigerant, but the boiling and condensation properties of those liquids don’t work well under normal cooling conditions or they are uneconomical to produce.

The expansion valve itself is not actively accepting or rejecting heat (there will be some ambient heat transfer if the valve is exposed). When the pressure drops the mixture starts to boil and the temperature drops as the heat of evaporation is extracted to support the saturated mixture of liquid and gas. Now the low pressure side of the expansion valve is the place where you have truly cold refrigerant.

At this point in the cycle the air conditioner wants to put this cold refrigerant through a heat exchanger and transfer heat from the air in a room back to the refrigerant. The now low pressure, low temperature liquid/gas refrigerant mixture is sent into a heat exchanger called an evaporator. It’s called an evaporator because the warm air from the space is passed by a fan over coils containing the refrigerant and the heat in that air is transferred to the refrigerant causing it to thoroughly boil and change completely back to a gaseous form (saturated liquid/gas to a superheated stream of vapor).

Remember that the refrigerant is at a much lower pressure now. Like water boiling at a lower temperature at high altitude, so will the refrigerant boil or change to a gas in this lower pressure environment and in the process soak up heat. Remember, heat always moves from hot to cold. So heat is naturally carried from the warm air to the cold refrigerant through the interface of the coiled pipe (usually copper pipe called the coil). The air emerges colder because the heat has been removed. The refrigerant vapor is now holding that heat and carrying it back to the compressor to start the cycle all over again.

High Head Pressure Fault: A Vicious Cycle

Back to the original question: What is a high head pressure fault?

A high head pressure fault is equivalent to a high temperature fault. There is a direct relationship between temperature and pressure for a substance in gaseous form (from thermodynamics). If temperature goes up then pressure goes up if the volume is constant. If you know anything about the container of the gas and if you know the pressure you can figure out the temperature. If you know the temperature, you can figure out what the pressure is. In this case pressure is used as the way to determine the state of the fluid after it has been compressed. If its pressure is high then so is its temperature.

High temperatures are a killer to compressors. If it goes too high it will literally break down the lubricant for the compressor and the compressor will destroy itself with metal on metal wear.

After the low pressure vapor coming into the compressor is compressed, its temperature rises because the pressure rises from the mechanical work done by the compressor. Energy is added through mechanical compression and the result is a high pressure, high temperature vapor. You are converting electrical energy to mechanical energy to thermodynamic energy ready to be unleashed again.

A high head pressure fault develops if the vapor returning to the compressor is too hot and the subsequent compressed refrigerant will also be hotter than normal. If there is too much heat in the refrigerant then it’s possible that the next step of putting it through the condenser to throw off that heat will not fully condense the refrigerant into liquid form. At that point you have a degenerating refrigeration cycle where the refrigerant never makes it completely to liquid form in the condenser before being sent to the expansion valve. The expansion valve works because you have high pressure liquid being converted to a saturated mixture of gas and liquid at lower pressure.

Therefore, you can’t put a gas through an expansion valve and get the refrigerant to cool down because cooling of the refrigerant occurs when pressure is released from a liquid and it starts to become gaseous. If it’s already mostly gas then no significant expansion or flash cooling can occur. Soon no more heat will be absorbed and all of the refrigerant cycle will be in gaseous form. The compressor eventually overheats and destroys itself from rapidly increasing temperatures (getting hotter because heat is still coming from the space as well as mechanical heat added by the compressors.)

So the problem with having high head pressure is that it is an indication that the refrigeration cycle is broken and there is no use in trying to exercise it further. You are in a vicious cycle. The unit has to shut down before it destroys the compressor and this is why most modern systems have a safety cutoff in the case of high head pressure.

What failed in order to cause a high head pressure fault?

Ultimately a high head pressure fault is caused by excessive heat in the system. That heat could be coming from a super hot room that you’re trying to cool. It could come from the accumulation of heat from a poorly functioning condenser unable to throw off the heat the system is picking up and many other reasons including overcharging the refrigerant. Let’s look at some of these problems and why they lead to a high head pressure fault.

Condenser Blockage

Most high head pressure faults will be on the condenser side of the system; the unit usually on the roof or outside the building. One of the main problems is a physical fouling of the condenser fins which restricts air flow over the coils. If air isn’t moving well over the fins and coils then there won’t be as much heat transferred and therefore less heat is ejected from the system.

As outside temperatures rise or the internal load rises, more and more heat will need to be rejected. It’s possible to have more heat to reject than the condenser is able to throw off. This leads to higher temperatures and therefore higher pressures at the expansion valve. More heat ends up in the expanded refrigerant reducing the evaporator efficiency and that leads to higher temperatures and pressures of the vapor returning to the compressor. It’s a bad cycle that only gets worse unless the heat load is dramatically reduced or the unit is shut down.

In the case of our customer’s Liebert system, cottonwood seeds began to accumulate and block the air flow across the condenser eventually causing the condenser to not keep up as temperature rose and a high head pressure fault shut down the system. Short cycling began as it reset itself a number of times before shutting down for good when ambient air temperatures reached about 105 F.

Damaged fins

Other causes of condenser inefficiency include damaged condenser fins. If you’ve been up close and put your hands on these fins you know they are quite easy to bend. Once they’re bent then no air can flow over that section of the coil reducing the overall efficiency of the condenser and therefore the condenser can’t reject as much heat. If the damage to the fins is excessive it can dramatically reduce the heat load the system can handle.

We’ve seen examples where an overzealous maintenance person has directed high pressure spray across the fins and flattened entire sections. What started out as an operation to improve the condenser efficiency by cleaning the fins and coils ended up damaging and reducing the condenser efficiency.

Liebert Computer Room Air Conditioner with flattened condenser fins

The photo above is a picture of one of the Liebert units on a data center in Fort Worth that we’re monitoring. On the left side you can see bright spots on the condenser fins. These are small pockets of bent over fins and might have been caused by hail.

What’s more disturbing is shown on the right half of the unit where you can see large swaths of condenser fin damage where the fins are literally bent over. This is clearly not caused by hail damage and almost certainly caused by the incorrect use of a high pressure sprayer. You can imagine how much less efficient this condenser is and can only imagine what happened next when cottonwood seed began to get trapped against the working side of the condenser.

Refrigerant contamination or internal coil fouling

A less common cause of condenser inefficiency occurs within the condenser coils itself. If the refrigerant has been contaminated in the past it’s possible for the coil itself to begin to plug. This reduces the flow of refrigerant through the coil and in turn reduces the amount of heat the condenser can throw off.

Very hot room

Because high head pressure issues are caused by excess heat in the system, you may need to look at other ways heat is getting in the system. One potential problem comes from trying to cool down a hot room. If you have a run-of-the-mill high head pressure fault and things were running well before, then it’s probably not going to be this reason.

Applications of commercial refrigeration run into this sort of problem all the time when they start up a walk-in refrigerator or freezer for the first time. Commercial refrigeration systems aren’t really designed to take down a heat load in a box coming from room temperature or higher. They’re usually designed to pull much smaller quantities of heat out of a box that is already pretty cold. For this reason you will often see special start up instructions that give specific sequences on how to get a walk-in refrigerator started up; methods to slowly cool the space rather than getting it to operating temperature quickly.

Similar issues come up in commercial refrigeration if a large load of room temperature product is added to a running refrigerator. Manufacturers of these appliances usually know how much warm product you can load into the refrigerator without causing a problem.

Refrigerant load that is overcharged

At a high level it’s easy to think that more refrigerant is better. But if you’ve understood a number of things so far about the refrigeration cycle, then you’ll understand that more is not necessarily better. The primary reason is that if there is too much refrigerant then the condenser itself will be flooded to some extent.

The job of the condenser is to condense the vapor to liquid and it needs to be liquified by the time it exits the condenser. But if there is too much refrigerant then there will be too much of it in liquid form inside the condenser. As soon as a portion of the condenser has liquid in it then that part of the condenser will not help phase change the refrigerant and the condenser is less efficient and unable to handle a higher heat load.

A flooded condenser from overcharging causes problems similar to the fins being damaged or blocked because the ability of the condenser to throw off heat has been hampered.

Failed Condenser Fan

That’s a pretty detailed look at the underpinnings of a high head pressure fault and a few common causes. Next, let’s look at another high head pressure fault condition. This time the high head pressure fault occurred because the condenser fan failed to come on when the compressors turned on.

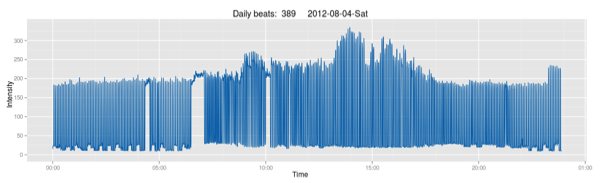

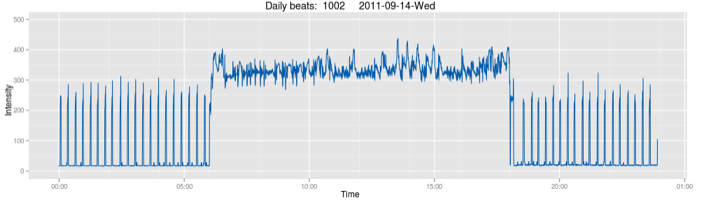

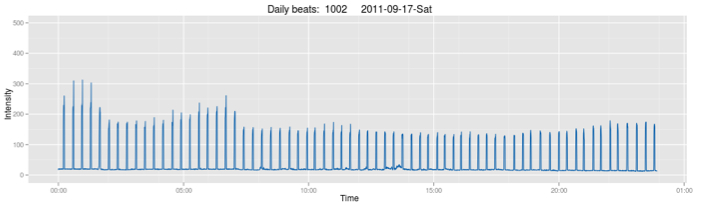

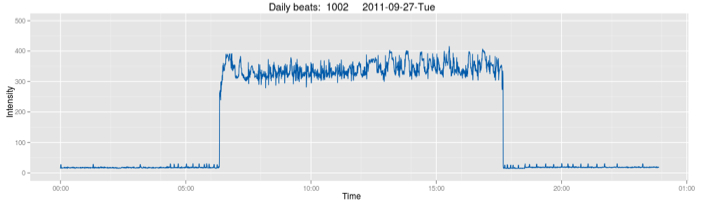

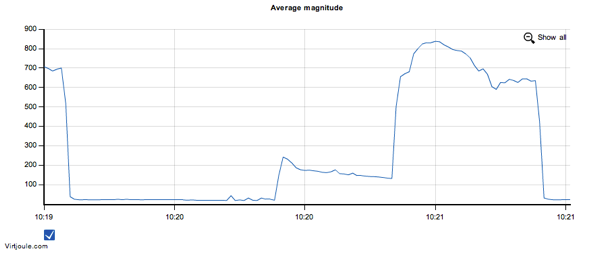

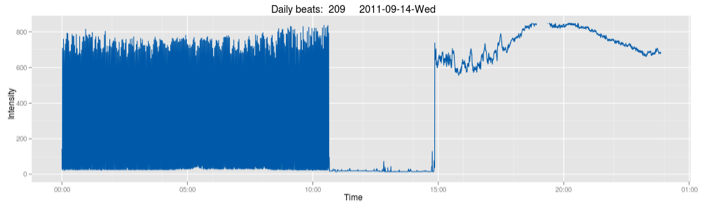

Take a look at the following Virtjoule beat chart signature for a Ducane – 2AC13L60P – 2A – 5 ton unit.

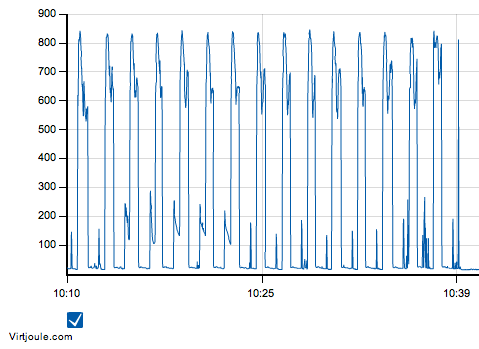

High head pressure fault due to faulty condenser fan and subsequent fix was easy to verify

The solid part of the graph is indicating that the unit is turning on and off hundreds of times a day. We had seen this activity as soon as the sensor was installed and it was obvious that there was a problem.

The maintenance man for this unit called his HVAC company to make a service call. A few days later he was under the impression from them that the problem had been fixed earlier. The signature continued to prove otherwise. We notified the customer of the situation and suggested they shut down the unit until it could be fixed. You can see the shut down occurred just after 10 am. The unit was then fixed that same day and restarted about 3 pm. It is extremely easy to verify that the maintenance was performed.

Ducane 5 ton 2AC13L60P with a bad condenser

Short cycling can be an indicator of a high head pressure fault

This is certainly a short cycling situation and short cycling is one of the indications that the refrigeration cycle is broken. We were not able to tell exactly why this was occurring, but without a Virtjoule sensor on the unit the second situation could have continued until the compressor was burned out. When standing by that unit it was pretty obvious what the problem was when you could hear the compressors turn on, but the condenser fan never turned.

If the condenser fan motor or relays to turn on the fan are broken then no significant air flow will go over the condenser. Thermodynamically this is the same thing as having blocked condenser fins or even restricted refrigeration flow inside the coil. The condenser simply can’t operate well enough to throw off all of the heat that is required. Eventually the cycle turns to high temperatures and pressures and the safety switch is thrown to shut down the unit.

Many of these units will reset the high head pressure fault automatically and the unit will attempt to try again. That’s what was happening in this case. The unit could actually run for a little bit because there was enough ambient heat rejection to keep the cycle going for just a minute or two before the high head pressure occurred again. The unit shuts off and cools off and it starts all over again…hundreds of times a day in this case with all the associated wear and tear and wasted energy.

Conclusions

I should be clear that currently the Virtjoule alert system does not directly diagnose high head pressure faults. We wouldn’t have known exactly what the cause of the problem was, but we did see that there was a serious problem developing.

In both cases presented here, even though the cause was different, there were short cycling indications directly observed and that is something that can be alerted on. We also alerted on the fact that the computer room air conditioner shut down and the Liebert system did not send an alert.

A high head pressure fault is a low level refrigeration cycle failure that could be caused by a number of reasons. Even the machines that are throwing those faults aren’t diagnosing the problem.

What has been useful to our customers is the ability to see that the machine is operating in an unhealthy state or not operating at all because of the problem. Then the problem can be looked at and fixed before expensive damage or a major inconvenience occurs.

[Randy Cox - CTO and VP of Software Engineering, Virtjoule - He is the software designer and analytics engineering for Virtjoule Sense sensors. He studied Chemical Engineering and Petroleum Refining at the Colorado School of Mines. You may contact Randy at: randy at virtjoule dot com]