Summary:

As a young company, we’re still learning the range of things that are possible with the Virtjoule solution. In the last year and a half, we’ve discovered that not only has the technology met our original vision of functionality and price, the types of projects that can be accomplished are even more varied than we thought. The Virtjoule solution has been installed on everything from beverage coolers to a 6,000 ton cooling system on a major Las Vegas hotel.

We often get asked, “What kind of projects can you do?” In the earlier days of the company, the answer was in the form of suggestions of what we ought to be able to do. After all, we had a device that could pick up vibration and the ability to track that vibration over time and see patterns emerge.

These days, the answer is educated by field experience with the problems and the economics of solving those problems for our customers. At the highest level, the answer is “If it vibrates, we can monitor it.” As a company, we’ve done work in the various segments you’ll see in the list below.

To get a handle on the range of applications, perhaps it’s useful to take a scan across the types of units that we’re currently tracking.

| Function | Model |

| Beverage Coolers | Micro Matic MMPP4301 |

| Walk-in refrigeration | Numerous models of Harford Duracool Harford Duracool – H1984A8 Trenton – TEHA025L6-HS2A-F – 2.5 hp Trenton – TEHA006E6-HS2B-B – .6 hp |

| Air conditioning – Split systems | Ducane – 2AC13L60P – 2A – 5 ton |

| Package units |

Trane YSC048A3EMA2U – 4 ton Trane YSC060A3EMA3 – 5 ton Rheem RKKA-A073CL10E – 6 ton Carrier – 48TCEA07A2A5A0A0A0 Bard PH13062 Bard PH1060-B – 4.6 ton York D1NA042N05625C – 3.5 ton York D1EB048A25B – 4 ton York D2NA060N09025D – 5 ton York DM090N10A2AAA4B – 7.5 ton York BP090C00A2AAA4A – 7.5 ton York D1EB060A25B – 5 ton Johnson Controls – J05ZJN10D2AAA1C – 5 ton Johnson Controls – J07ZHN15P2AAA4B – 7.5 ton Johnson Controls – J10ZHN20S2AAA4B – 10 ton Johnson Controls – J25ZJN32S2BZZ10001 – 25 ton York ECO2 50 ton Carrier 48P5 Horizontal VAV 100 ton McQuay 40 ton McQuay 70 ton |

| Heat pump packages and split systems | Heil Tempstar – NHP060AKC1 – 5 ton Coleman/York – HP060X1021A, 5 ton split system Goodman CKL60-1 – 4.75 ton Goodman CPLE60-1 5 ton Goodman GPH1324M41AB 2 ton York 20 ton |

| CRAC-(Computer room air conditioners) | Liebert |

| Evaporative Coolers – Water pumps | Can’t divulge manufacturer at this time |

| Air handlers | Goodman AH120-00 |

| Commercial Refrigeration Compressors | Copeland Copelametic 4RA3-100A-TSK-800 Copeland Copelametic 6RA4-200A-TSK-800 Copeland Discus 3DB3F33KE-TFC-800 Copeland Discus 4DL3F63KE-TSK-800 |

| Chillers | York – 18 ton Carrier 30GTN090 90 ton |

| Cooling towers | Baltimore Air Coil, 125 hp electric pump and 100 hp VFD fan – 2,000 ton |

One of the most satisfying things that we’ve seen is that this is a huge range of equipment, all being monitored by the same Virtoule Sense technology.

If you’re familiar with some of the pieces on this list, you’ll know that some put off so much noise and vibration that you need ear protection. Other pieces are so quiet and smooth that it’s very difficult to tell if they’re running when standing right next to them or even putting your hand on the machine. I’ve been particularly impressed with the Trane series (YSC060A3EMA3) as very smooth operators in package units.

Because the Virtjoule sensor is self-calibrating, once it’s installed it can start off as a very sensitive device and self calibrate to the point where it can handle large magnitude vibrations. This self-calibration means that the installation is roughly the same for all of these installations, stick it on, power it up, and start getting data. An operating signature will always emerge that can be analyzed, reported on, and alerted on.

Customer and facility types

The table above is specific to equipment and equipment applications. But what sort of customers and markets does this represent? Here’s one look at the type of facility and customer:

- Executive office buildings

- Restaurants

- Strip malls

- Small market and convenience store refrigeration

- Data centers

- Hotels

Some are very high energy users where control problems or equipment degradation can cost thousands of dollars a year if the problem isn’t corrected. Some have equipment that might not burn a lot of energy, but the unit is serving high value contents. Food, pharmaceuticals, and computers are good examples of high value contents that need to be protected from catastrophic loss.

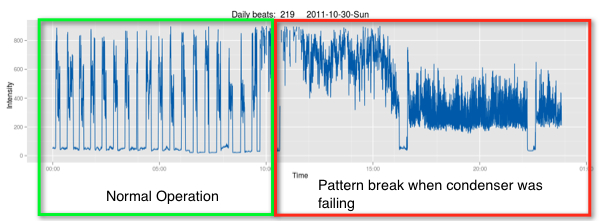

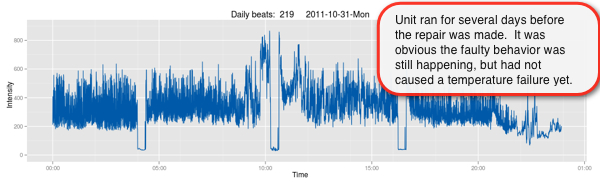

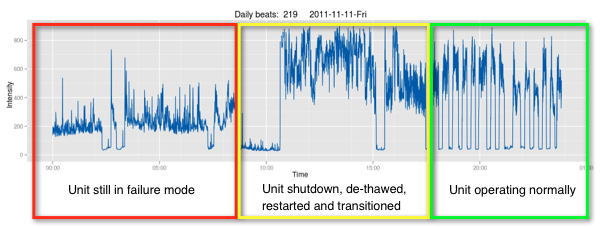

In a recent example, Virtjoule was able to give the owner of a walk-in refrigerator days of notice that their unit was degrading. The customer was able to get a refrigerant leak fixed before they lost control of the temperature of the cooler. One of my upcoming blog articles will discuss this “catch”.

If I were to sum up our results since we started, I would say we’ve helped customers save money by identifying control problems or system degradation that were racking up extended hours and energy bills. And we’ve helped some customers avoid serious loss of high value contents that were being refrigerated.

What new applications will we see this year? I can’t wait to find out.

[Randy Cox - CEO and co-founder of Virtjoule - He has been the software designer and analytics engineering for Virtjoule Sense sensors. He studied Chemical Engineering and Petroleum Refining at the Colorado School of Mines. You may contact Randy at: randy at virtjoule dot com]