Summary

You might call a 300 hp Caterpiller natural gas fired engine, powering a huge fan and compressor, the ultimate piece of HVAC equipment. We call it just another day of critical machine monitoring for Virtjoule. Instead of monitoring machines to cool contents of walk-in refrigerators or occupants of buildings, this time the compression and cooling that is occurring is for the benefit of natural gas being pumped into the interstate gas pipeline system.

A solar powered version of Virtjoule Vibe, is uniquely suited to monitor these large pieces of equipment at Priority Oil and Gas pipeline locations in western Kansas. Using a vibration microphone, Virtjoule Vibe monitors vibration from the huge compressor engines and can tell the oil field service, LaRana Resources, when they are down. A previous system requiring a long distance radio connection was much more power hungry, expensive, and less reliable than the Virtjoule system.

Caterpillar engines that drive the compressors can fail from a variety of reasons including engine oil temperatures, bitter cold and frozen gas fields in the middle of the winter which starve the gas supply, blown turbo chargers, cracked cylinder heads, cracked manifolds, etc. Virtjoule isn’t figuring out what those reasons are, that’s LaRana Resources’ job. But Virtjoule is on guard 24 hrs a day ready to alert LaRana field engineers if the compressor shuts down. If you thought they just punch holes in the ground and watch the bank account grow, you would be wrong.

Key Points

Virtjoule Vibe gives more information and is more reliable than other oil and gas industry specific solutions.

Multiple alert mechanisms give Virtjoule Vibe flexible 24 hour alert capability including text, email, and voice callout.

Applications where there is no electrical proxy for runtime activity makes Virtjoule Vibe a clear choice.

Cellular coverage from our national carrier, Verizon, is amazingly good and the sensors can pull in almost anything if it’s there. The nearest cell tower that we know about is about 15-20 miles away from the various locations that we’re monitoring.

Remote locations can really benefit from our cellular approach. Even though there is cellular coverage, there is no local internet connection or phone line anywhere close to these machines.

Role of Natural Gas

It doesn’t matter where you stand on the expansion of natural gas production in the United States, most people agree that domestic natural gas production has helped create a certain amount of energy independence and is one of the cleanest methods of producing energy from carbon sources that we have. The underground Niobrara formations in eastern Colorado (Phillips and Yuma counties, and others) and Western Kansas (Cheyenne County), have been prolific producers and Priority Oil & Gas and LaRana Resources are teamed up on wells that are tapping these resources. I grew up in northeastern Colorado and have seen natural gas production expand many fold over the years in that area. My chemical engineering and petroleum refining education has given me good insights into the processes required to bring natural gas to market.

The Compressor Station

The natural gas compressor station provides a critical role in getting natural gas to the interstate gas pipeline and on to the market. These stations collect gas from many wellheads in the area and compress that gas up to the pressure required to move it into the pipeline. The gas is compressed in several stages as it would be much too difficult to compress to pipeline conditions all in one stage. Also, as you compress any type of gas, it will heat up. Gas that is compressed must be cooled some amount after it is compressed to avoid adding a lot of extra heat to the pipeline system.

The photo below is of one compressor station Virtjoule is monitoring. 12 VDC power is used to power the sensor that can run on anything between 12 VDC to 24 VAC. That 12 VDC power is provided by the solar panel you see on the building. Inside the gray box under the solar panel is a 12 V deep cycle marine battery and a solar charge controller.

This gray box is also housing a much more expensive monitoring system specifically designed for oil and gas companies that Virtjoule is replacing. Both monitoring systems are being run in parallel, but much of the time the other system is not operational.

The huge fan that you see on the left hand side of the photo is part of a gas cooler that itself is attached to the big Caterpiller engine inside the building. Air is exchanged across tubes in the cooler while the hot gas flows through the tubes. Virtjoule’s vibration microphone is literally attached to this cooler just inside the building. The cooler has a hard connection to the compressor and engine and so it vibrates with the engine. If the engine isn’t running, nothing else is happening in this building. Compressed gas is then routed outside the building to go through a dehydrator to remove extra water vapor that comes up naturally with the gas. Some fields have more water in the gas than others and the amount of dehydration needed varies from field to field.

As you can imagine, safety is important when working around this much natural gas. There is no other electricity in the building except from the solar DC system. In a smaller booster pump station that Virtjoule is monitoring in the same field for an owner based in McAllen, TX, Virtjoule is powered off of a standalone battery and works for many weeks before they replace the battery with a charged one. LaRana engineers visit these sites at least once a day, so occasionally putting recharged 12 V battery in is no big deal. Virtjoule’s sensors are very low power and so the drain is not large. Adding Virtjoule to the current solar setup has not caused any problems.

Fault Detection

Although these engines have throttles and they are sometimes operated at less than full throttle, for the most part they are running all-out all of the time. This is pretty straightforward runtime fault detection for Virtjoule. It’s always supposed to be running. There’s no purposeful cycling and no short cycling faults like you might see in HVAC machines.

As a point of interest, if you’re standing in the building shown above, the ground shakes. The building shakes. There is no missing the fact that the compressor is running. These effects far overwhelm any noise from wind or rain. We’ve had no problems distinguishing the difference.

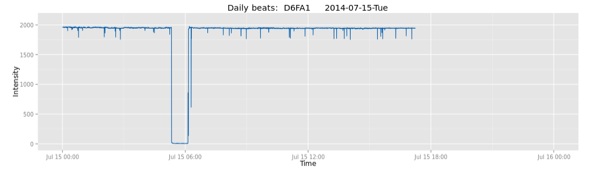

LaRana Resources has a small group of super smart field mechanics. Kevin Andrews, VP of LaRana, has the mechanics on shift rotations as they’ve found that these compressors can go down any time of day or night. They also purposely bring them down roughly once a month for routine maintenance for either the engine, pipeline, or other mechanical issues. Just this morning, the compressor they dub “Cherry Creek” went down about 5:00 am for a little over an hour. We see the calls go out at all times of day or night and know that someone may have gotten out of bed and are driving to the site. Depending on the problem, the mechanic may be there for a very long shift or even making a mad dash to Denver to pick up parts for the engines.

Alerts also go out to Melissa Gray, business and operations manager at Priority Oil & Gas. Everyone wants to know when these things go down. Melissa has mentioned to me in the past that it can cost $500/hr or more when a compressor goes down.

Other Benefits

Melissa has also seen other benefits by using the Virtjoule system. For starters, since Virtjoule keeps all the runtime history of the machine, she is able to determine the service level of the compressor. Priority Oil & Gas used to own these compressors, but now actually rent them from a supplier. Let’s just say the rental would make your rent or mortgage look small. As such, it’s important to get the most out of these machines and if they’re not performing up to the service level set by the supplier she can get a rebate on the monthly fees. Virtjoule machine history makes our $29.95/mo look really cheap when our service does both fault detection and provides the runtime history for such an important and expensive piece of equipment. Virtjoule never throws away runtime data, no matter how old it is.

Conclusions

Virtjoule’s ability to monitor the vibration of a machine is particularly well suited for industrial gas compression where compression is done not by electric motor, but by a natural gas fired engine. Because Virtjoule is based on a cellular chip in each device, there is no need for an internet connection to be brought in or any need for a telephone line. These compressors are amongst farmland, pasture, and prairie land. They’re in range of a Verizon cell tower, but any other communication method would be thousands of dollars more expensive…one of the reasons Virtjoule is a good fit in oil & gas applications.

[Randy Cox - CEO and co-founder of Virtjoule - He is the software designer and analytics engineer for Virtjoule Sense sensors. He studied Chemical Engineering and Petroleum Refining at the Colorado School of Mines. You may contact Randy at: randy at virtjoule dot com] – See more at: http://blog.virtjoule.com

|