Summary

I wanted to share some of the results we logged when creating air dams to simulate various fault conditions on a Bard wall mount air conditioner, commonly used on mobile buildings and construction site trailers. The unit we tested was missing placards, but the trailer it was mounted to suggested it was built in 1996 and there was every reason to believe this unit was the original. We think it was at least 15 yrs old.

One long held premise was that dirty air filters would make a significant impact on the machine. It turns out that it’s very difficult to impact these machines directly by blocking the flow through the air filter. They are “leaky” enough that air will find its way through one way or another, transferring dirt problems on to the evaporator coils. There is not a tight seal around the filter. You can have a completely blocked filter and if the evaporator coils and condenser are clean, the unit will behave normally without any change.

It was shown that a severely blocked evaporator coil or condenser coil can cause runtimes to soar 300% – 600% or more over normal operations. This type of degradation is easily detectable via runtime monitoring like Virtjoule does with either vibration or CT/Amperage monitoring.

We know these units survive in very harsh environments and I think you’ll see from the results below that they are extremely robust. Cooling still occurs even while the unit is degrading severely. This does give the opportunity to detect this degradation and be able to do something about it before complaints occur.

Anatomy of a Bard wall mount air conditioner

Project Goal

The conditions I wanted to recreate have shown up on repair bills for these types of units. Of the field failures reported to us, dirty evaporator coils and condenser coils were two problems that were mentioned frequently. It wasn’t clear from the reports if the repair person thought those issues were part of the problem or whether cleaning was performed as a part of good maintenance practice while he was there. In one case the repair bill mentioned a highly “impacted” filter meaning it was very well blocked so the conditions affecting that filter could very well impact the condenser and evaporator coils with dust and dirt.

Test Strategy

There were four main tests that I ran. All involved restricting or blocking the condenser coils or the evaporator coil air flow similar to what would happen if dust, dirt, mud, or damage clogged the fins. I’ll show you pictures of the test as well as the recorded results.

A fifth test that I wanted to run, one that would simulate a failure mentioned in the repair bills, was to disconnect the condenser fan fully to simulate a broken fan or faulty relay that fails to start the condenser fan. This is an occurrence we’ve experienced in the field on a number of occasions with our customers. I didn’t have time for this and it was a bit more invasive than I wanted to do, but next chance I get I’d love to measure the results.

Unable To Force Short Cycling Condition

Knowing how the machine responds to a broken condenser fan would be an important pattern to understand. In many cases we’ve seen in package and condenser units, the machine will short cycle endlessly starting and stopping the compressor on very short intervals, 30 seconds or less, which is very hard on the compressor and in some cases the repair of the fan required a replacement of the compressor at the same time due to the damage. This is not to mention all the extra energy costs for the customer to start and stop a compressor that much.

I was not able to get short cycle behavior from the air dam tests. I think that was primarily because the condenser fan was in fact running and even though air was not going all the way through the condenser fins, it was still bouncing off the inside of the condenser and probably accomplishing some heat rejection effect despite our efforts to block the flow. Unhooking the condenser fan would be an interesting test that I was not able to fit in.

Test #1:

Goal: Determine standard runtimes with unit in existing condition

Evaporator condition:

This is a photo of the existing evaporator coils. This turned out to be, by far, the dirtiest evaporator coils I saw on the dozens of units I’ve inspected. My estimate is that these coils are 15-20% blocked including this spot in the upper right hand corner and the condition of the rest of the coils.

Condenser coil condition:

The condition of the condenser coils was decent. I did a mirror based inspection from the back where I slid an inspection mirror inside the condenser fan shroud and angled the mirror such that I could look through the fins to the daylight back to the outside. Needless to say, this is not an easy thing to get a picture of. Although not perfectly clean, there was no significant blockage from what I could see.

Air filter:

The air filter was in pristine/new condition

Return air filter:

The return air filter was in pristine/new condition

I set the thermostat in the building to 65 degrees. I did not check temperature inside since it was not a concern in this test with the exception of getting it set such that the machine would cycle on and off enough to make for a convenient test.

I did let the building come down to temperature over the course of an hour and a half or so before starting any tests. The interior of the building was cool.

Normal runtimes averaged about 6 minutes of compressor time with an additional one minute of blower time after the compressor shut down. Some cycles were much shorter. The building was at this equilibrium for about five cycles before the tests began. Outside air temperature at this time was logged at 73 degrees using the nearest Yahoo weather station. The temperature did not change during the course of the tests.

Average compressor runtime: 6 minutes

Test #2:

Condition: Significantly blocked air flow coming out of the condenser. Simulate dust plugged condenser coils or damaged condenser fins.

With the help of a mechanic on site, we fashioned a piece of plywood that could be screwed onto the outside of the condenser in place of the condenser fin cover. The idea here was that we would start with significantly blocked air flow and then be able to apply duct tape to further restrict flow as needed.

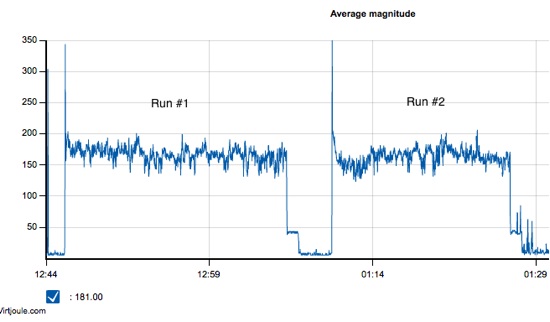

With this dam in place, the runtime on the unit rose noticeably and significantly. I did two tests.

First run: 21 minutes

Second run: 17 minutes

Average runtime: 19 minutes

300+% increase in runtime over normal conditions.

If you put your hand up over the air flow coming through the holes, that air was hot compared to the air flow coming through the fins under normal conditions. This suggests the unit was rapidly building up heat and not successfully rejecting the heat of compression.

It’s also the case that the magnitude of the signal also increased, probably due to the extra vibration effects of back pressure on the fan due to lower air flow. We don’t typically take action based on the signal magnitude, but it is worth noting that there was a significant rise in the signal magnitude. We don’t often have the privilege of putting a machine through the paces like this to actually compare fault scenarios to normal conditions.

Test #3:

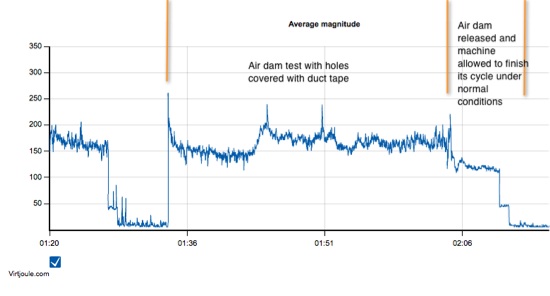

Condition: Fully blocked condenser covering holes with duct tape. Simulate dust plugged condenser coils.

It turned out that it was much more difficult to restrict the air flow over the condenser than I would have thought. I used duct tape to tape over the fairly small holes in the board. The problem is that as the refrigerant gets hotter and hotter, because of the restricted air flow, the temperature on the tape was also getting hotter and hotter. Eventually the tape glue was too weak to hold. However, I did get a run in with this condition while standing on the ladder pushing the duct tape back down.

Interestingly, the drain holes in the bottom of the cabinet ended up serving as additional air flow outlets when the condenser is blocked in this way. I continually had to find ways to reduce the air flow as if the condenser itself was blocked. I taped over those drain holes part way through the test when I realized it was another escape path. By the time I was done it was pretty absurd what had to happen to completely block it, suggesting that even in the worst conditions in the field there will still be air flowing over the condenser unless the fan itself is broken.

It was also interesting to note that if you put a tissue up to the side grates under normal circumstances, the tissue would stick to the grate because of the air flow going into the cabinet from the sides and out the front. With the air flow restrictions in place, the air flow became very turbulent and some places on the grill would be pushing air while other places were pulling air. This does suggest that cooler outside air was getting into the condenser fan area and providing some heat transfer.

With this extra restriction, the runtime zoomed higher. Now looking at the previous test, it’s obvious even a little air flow helped a lot. Nearly complete restriction of air flow caused very long runtimes.

I believe the slight amount of heat rejection that was still taking place is the reason I never saw short cycling in this machine due to a high head pressure fault.

There was some cooling still taking place judging by the hand check at the interior air outlets. I believe this is because the condenser is multi layered and despite my best effort to shut off air flow there was still some heat rejection taking place on the back side of the condenser…the side facing the fan with that turbulent air getting mixed around in the cabinet.

I did terminate the test after 30 minutes so as to not put the machine under too much stress and to save some time for additional tests. Quite possibly if I had let the machine continue it might have heated up enough to produce a high head pressure fault. The outside air temperature at this time was still 73 degrees.

After the 30 minutes were up, I removed the dam and let the machine come to its normal state. Because it was so hot it took a full normal length cycle to cool down and shut down. So the entire runtime was just over 35 minutes.

This test showed that a blocked condenser would likely radically raise runtimes. Even after I stopped the test before the machine faulted or reached the setpoint, the runtime had already exceeded 600% of the standard runtime.

600% plus increase over standard conditions.

Test #4:

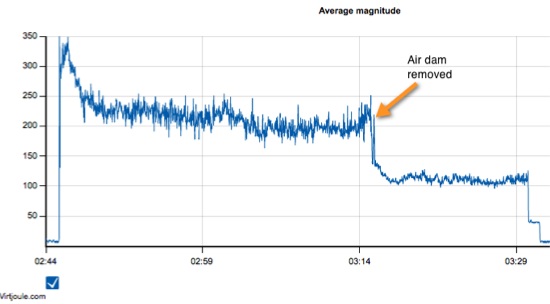

Condition: Fully blocked condenser using dam with no holes. Simulate dust plugged condenser coils.

After the struggle to keep the duct tape in place, we completely blocked the condenser using a piece of interior paneling material. I re-ran the test to see if there was any significant difference.

I didn’t expect much of a difference, but their was in two aspects. First is that the signal magnitude was the highest of any of the tests suggesting that there was indeed less air flow through the condenser and more back pressure on the fan. I again terminated the test after 30 minutes and it took about 15 minutes for the unit to come to equilibrium again instead of the usual six minutes. Since I didn’t have any temperature gauges, I can only guess that the refrigerant was that much hotter during this run. But we still did not invoke a high head pressure fault or find short cycling in those 30 minutes. Outside air temperature was still around 73 degrees.

Again, this was a 600% plus increase in runtime over the standard condition and the test wasn’t allowed to run its full course. Full runtime to setpoint or fault could have been much higher.

Test #5:

Condition: Partially blocked evaporator coils using a dam with some holes. Simulate dust/mud plugged evaporator coils.

We measured the size of the evaporator and a mechanic cut me a piece of paneling and drilled many holes into it. We’re trying to simulate a reduced air flow over the evaporator coils. Evaporator coils will get dirty if the air filter or the return air filter in the unit is not changed. As air is sucked in by the blower, dirty air can come into the cabinet in other ways around the air filter. There is not a tight seal around the filter and, as we’ve proven in other tests on a similar unit. You can have a completely blocked filter and if the evaporator coils and condenser are clean, the unit will behave normally without any change.

I used lightweight aluminum wire to lash the air dam to the evaporator fins using the coils themselves on the sides as the tie down points. There was a pretty snug fit between the back of the dam and the evaporator fins.

Remember that this evaporator was already 15-20% plugged and was still satisfying the setpoint in 6 minutes before we put the air dam in.

The test was started and it too produced a significantly long runtime. However, it completed before my 30 minute cutoff in 28 minutes. I’m sure that it met the setpoint rather than shut down from a fault.

Interestingly, under these conditions, condensed water was pouring out of the condenser hose, more than under normal conditions. This is because the evaporator was getting extra cold due to the reduced warm air flow over the coils, a precursor to the evaporator coils freezing over. Because cold air can’t hold as much moisture as warm air the fact that there was an excessive amount of condensate suggests that the air flow was much slower and colder as we might expect. Less air flow over the evaporator, even though colder, didn’t allow enough air to enter the building to satisfy the setpoint as quickly as it normally would resulting in higher runtimes.

By the time I pulled the panel back off, I did not see any ice or frost, but the evaporator itself was very wet. It’s possible ice was there and already melted by the time I got the machine apart.

In other types of machines, an evaporator coil freezing over is usually caused by a clogged air filter or an extremely dirty blower that isn’t moving enough air. But we already know from the previous set of experiments on these machines that a clogged filter won’t inhibit the amount of air flow the unit can get. Problems in the evaporator side of the machine will likely come from dirty evaporator or a dirty or faulty blower, not a dirty filter.

What we’ve shown here is that any of the number of causes of low air flow over the evaporator will also show up in increased runtimes.

Summary

The air dam strategy, although not a perfect simulation, can show how common problems in the field can show up with increased runtime. We’ve shown in our other work that counting the number of cycles and cycle times can give you a good picture of the health of the machine.

We’ve also shown here that a dirty condenser or faulty condenser fan can cause refrigerant temperatures and runtimes to sky rocket, putting a lot of thermal and runtime stress on the compressor. This will always reduce the life of a compressor. If you see a large increase in runtime you can bet the unit is under a lot more stress and likely needs a service call.

|

Mike Sullivan |

Nicely done but it appears that these units are very robust and the conditions you subjected them to would probably not ever happen. So given typical long term loading of filters / coils how long would it take to get to say 150 or 200% run times?

randy |

Mike, unfortunately I didn’t have enough test time under pristine conditions to know how a clean unit would perform. So I don’t know how much runtimes were extended over the unit I was testing going in. If I would have had more time, it would have been interesting to get that evaporator cleaned up to do an “after” test and also get the condenser fan disconnected for a real condenser fan failure test.

We have seen field units approach these conditions in several ways. It’s not hard to completely plug a condenser coil if cottonwood seed is flying whether on top of a building or on a trailer.

On construction sites these units are also very prone to severe plugging from dust depending on their placement and this can happen quickly. The companies that lease these units know that trailers going to certain regions or put to a particular purpose are many times more likely to fail.

The other condition that does happen that would not only approach these conditions, but exceed them, is a condenser fan failure. I came away convinced that there was still heat being thrown off of the condenser even though air flow was blocked on one side. Air was being bounced off the fins and pushed out the sides where air normally enters because the condenser fan was still running in my tests. In the case of a condenser fan failure there would be virtually no heat rejected compared to what I found in the totally blocked condition.

So, yes, the tests were purposely and sometimes humorously extreme and I was impressed at how the Bard did its best to overcome these obstacles. However, conditions that I was trying to simulate can and do happen to the clients and leasing company.